Standard PV solar modules might be a good choice for supplying your home with solar energy. The cutting-edge technology of shingled solar PV panels, on the other hand, might pique your interest.

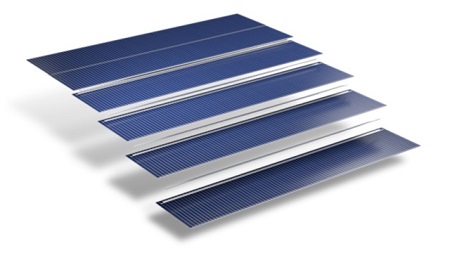

Solar cells that have been divided into five or six strips are known as shingles. The electrical connections can be created by layering these strips, much like shingles on a roof. An electrically conductive adhesive (ECA), which allows for conductivity and flexibility, is used to affix the solar cell strips together.

For your benefit, we will go over shingled solar panels in this article. Please keep reading.

What Are Shingled Solar Panels?

The main function of solar shingles is to absorb solar radiation to produce electricity, but they also serve as structural support for your home’s roof. Solar shingles are essentially roof shingles or tiles made of solar cells. Building-integrated photovoltaics is thought to include them.

Shingled solar panels, however, are not a structural part of your roof. The interconnection of this technology consists of cutting solar cells into a certain number of strips which are overlaid by connecting their edges using an electrically conductive adhesive (Thus, strings that are arranged into a panel structure are produced (ECA).

In other words, solar shingles serve to replace your existing roof while shingle solar panels are attached to the roof using the structural support from the existing roof.

Shingled Cell Technology

The market for solar modules has undergone a significant transformation recently, moving away from the largely ribbon-based interconnection of full-square solar cells and toward a wide range of cell formats and interconnection technologies that continuously increase power outputs.

One of those technologies is Shingled cell technology, which uses overlapping thin cell strips assembled either horizontally or vertically across the panel.

Shingled cells are produced by cutting a full-size, high-quality monocrystalline PERC cell with a laser into, typically, 5 or 6 strips. Depending on the size of the panel, the long strings of 34 to 40 solar cells are put together from the thin solar cell strips.

Electrically conductive adhesive (ECA), which allows for conductivity and flexibility, is used to affix them together.

This design allows shingled panels to produce more material per square meter. Because the cells in shingled modules run the full length of the module, they operate more effectively in conditions of partial shading. Additionally, these modules cost less to make and are less vulnerable to hotspots.

Benefits Of Shingled Solar Panels

Less Energy Loss Due To Shading

Since the individual cells in conventional solar panels are connected in series, the shading of a portion of the solar panel can significantly affect the amount of power produced. The shading losses can be significantly reduced by wiring the solar cells in shingles so that they can be configured in parallel and wired in groups.

Better Reliability

Low Busbar Failures

Busbar failures are decreased because shingle solar panels do not require the approximately 30 meters of busbar and soldered joints needed for conventional solar panels.

Better Mechanical Performance

As compared to conventional solar panels, the shingle approach is more resistant to failure brought on by external forces, according to static and dynamic load tests.

More Attractive

The clean, uncomplicated appearance of shingled solar panels and their superior street appeal are due to the absence of any visible circuitry.

In terms of performance, dependability, and aesthetics, shingled modules represent the current state-of-the-art in solar panel technology.

Shingled Solar Panels VS Conventional Panels

Composition And Structure

Type Of Cells

Both conventional and shingled solar cells are constructed from common semiconducting and light-absorbing substances, such as crystalline silicon, thin films, heterojunctions, or N-type IBC.

The layout or interconnection of solar cells, rather than their composition and structure, is the most significant distinction between conventional and shingled solar cells.

Interconnection Of Cells

Depending on the desired output, each solar panel has a different number of connected or arranged cells.

Typically, traditional modules can have 32, 36, 48, 60, 72, and 96 cells. Spaces separate the cells, which are arranged in a rectangular or square shape.

These gaps are then filled with copper busbars or ribbons using high-temperature soldering processes to provide interconnection between the solar cells. Traditional cells are also frequently linked in series.

On the other side, shingled modules avoid the use of ribbons, busbars, and soldering processes.

Instead, they divide their cells into 3 to 6 strips (using laser technologies), which are then strung together by attaching the front edge of each strip to the back edge of the strip next to it. With the placement of an appropriate electrically conductive adhesive, there are no gaps between the strips in that connection.

As a result, a continuous string of strips is produced, which can then be joined together to create shingled modules using ribbons and busbars. The parallel connection of cell strings in this instance is another significant difference.

Power Performance

Panel Power Output

These days, typical solar panels have a power rating of 300–400W. The market is home to a wide variety of models, some of which can even reach power ratings of up to 600W. Solar panels are made of shingles, in particular, ranging from 300W to 500W.

Panel Efficiency

The efficiency of energy conversion will vary depending on the type of cell and interconnection. The range of panel efficiency is 15% to 22.6%, regardless of whether you’re using mono PERC, half-cut MBB, or another type of solar technology. The shingled panels can still achieve efficiencies between 18% and 20.5%.

Furthermore, shingling can be used in conjunction with glass-glass and bifacial techniques, just like many other advances in PV module technology. Since more of the module can be covered by solar cells, shingling is a very suitable method for bifacial modules.

More light can be absorbed, and “back-escape” losses can be reduced, which normally occur when light passes through the gaps in traditional bifacial modules.

Mechanical Performance

When it comes to the dependability of any solar panel, module strength against external forces (such as wind and snow) is a crucial factor. The manufacturing process must therefore include load testing of PV modules.

When compared to conventional solar cells, the shingled solar cell approach is more resilient to failure brought on by external forces being applied to the panel, according to various static and dynamic tests of mechanical loading.

When tested using an IEC standard 5,400Pa positive load, shingled solar cells, for instance, show no power attenuation and no microcracks while a conventional half-cut cell module shows some microcracks and a slight power attenuation of around 1%.

Aesthetics

When compared to shingled solar cells, which do away with many of the ribbons and busbars found in conventional panels, standard panels may not be the most aesthetically pleasing option because of the numerous circuitries that are visible throughout the modules’ area.

Installation

On the top of your roof, installing conventional and shingled panels isn’t too difficult. The process of installing these two technologies is very similar.

Even if you use conventional or shingled roofing, it is always crucial to conduct a more thorough analysis with knowledgeable installers in order to properly size, install, and operate your solar system.

Are Shingled Solar Panels Better For You?

As we’ve seen, shingled solar cells are currently developing a variety of cutting-edge features for optimizing solar energy. This technology has made significant strides in the residential market so far, but it may take more time to establish a significant presence in the commercial and industrial markets.

However, more manufacturers and retailers are investing in solar shingled panels, which is leading to a greater supply and lower prices. This makes them a very promising technology. As a result, they are gradually becoming more available to all kinds of consumers.

Additionally, if you are someone who likes to have the latest cutting-edge technology then you would need to compare solar shingles and shingled solar panels. In this regard, shingled solar panels have a few significant advantages that can make them a much better option.

Final Words

Shingled modules are the most advanced solar panel technology available right now in terms of performance, dependability, and aesthetics. In conclusion, solar shingled panels are a fantastic option to take into account, especially in the residential market, making them applicable to any homeowner who wants solar on the roof, just like with traditional modules.